NOS PRODUITS  POMPES GPL

POMPES GPL

POMPES GPL

ken, NZ, SIHI ,

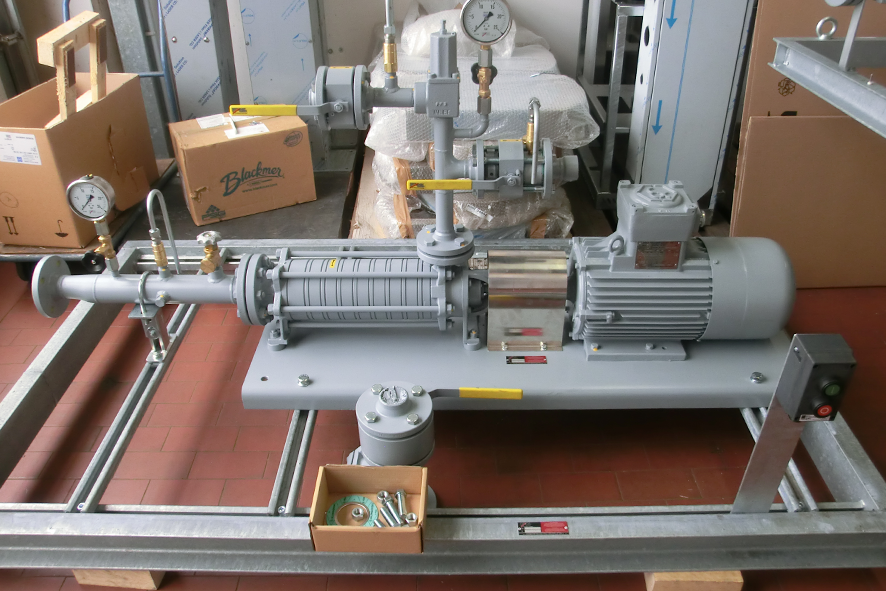

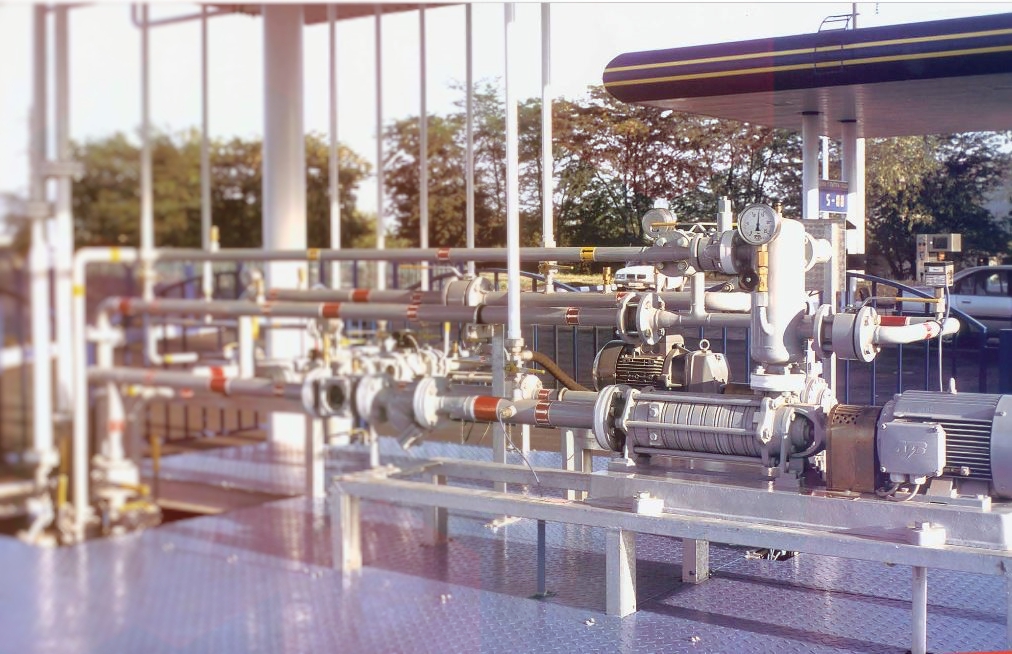

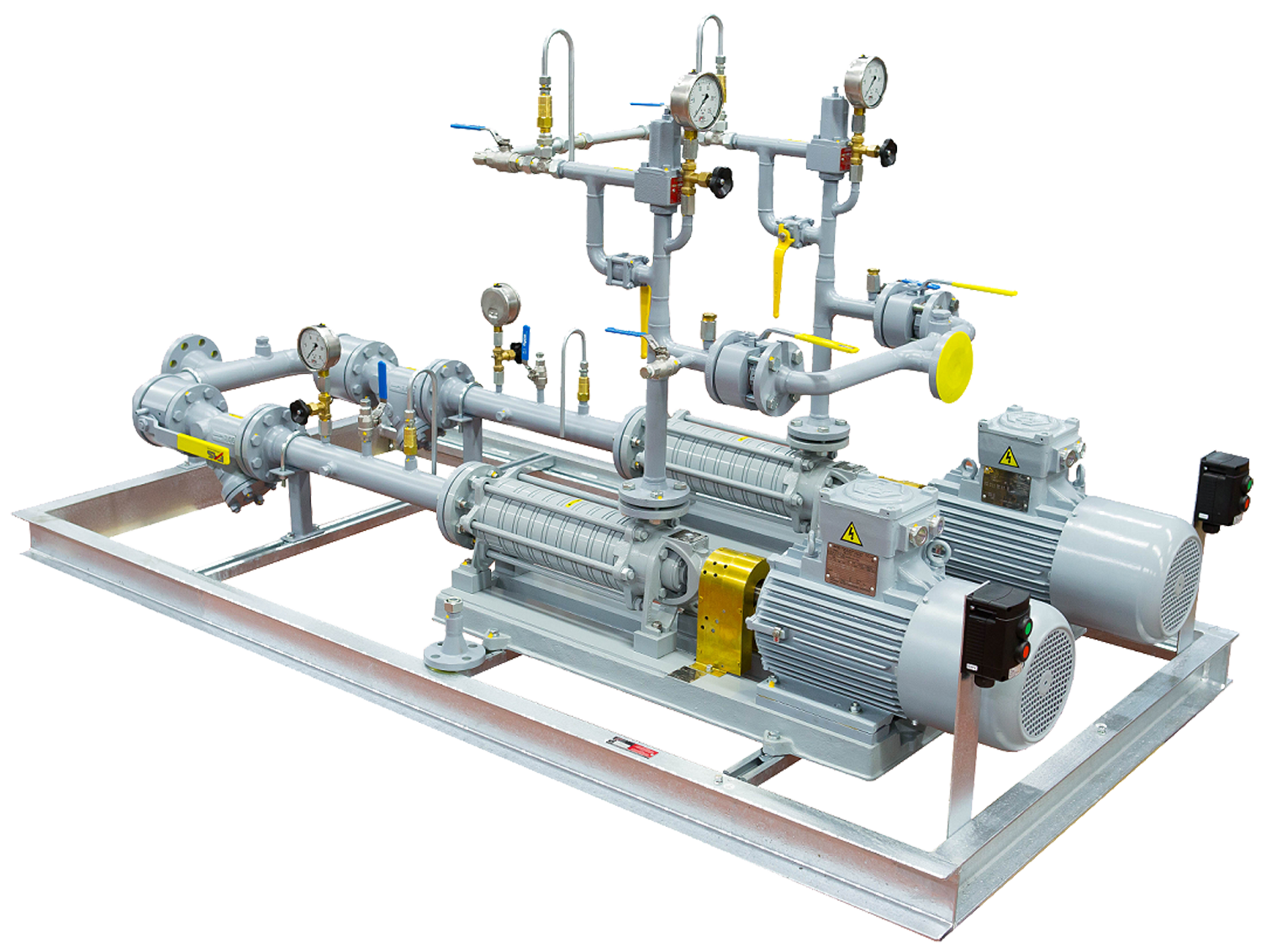

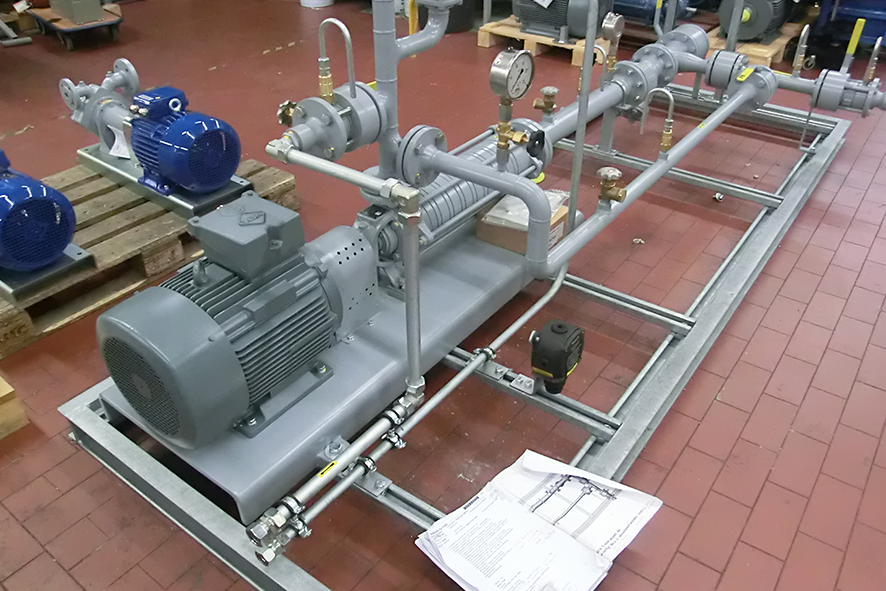

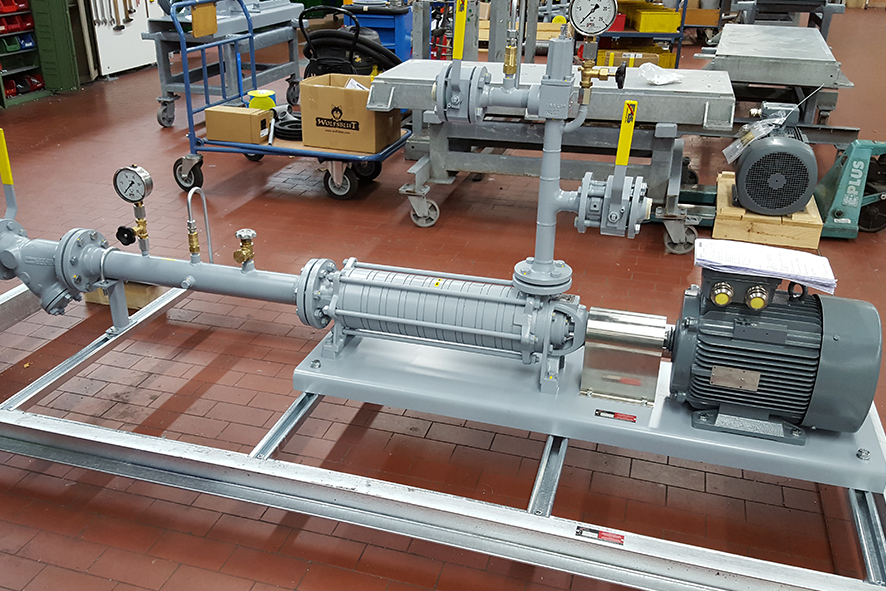

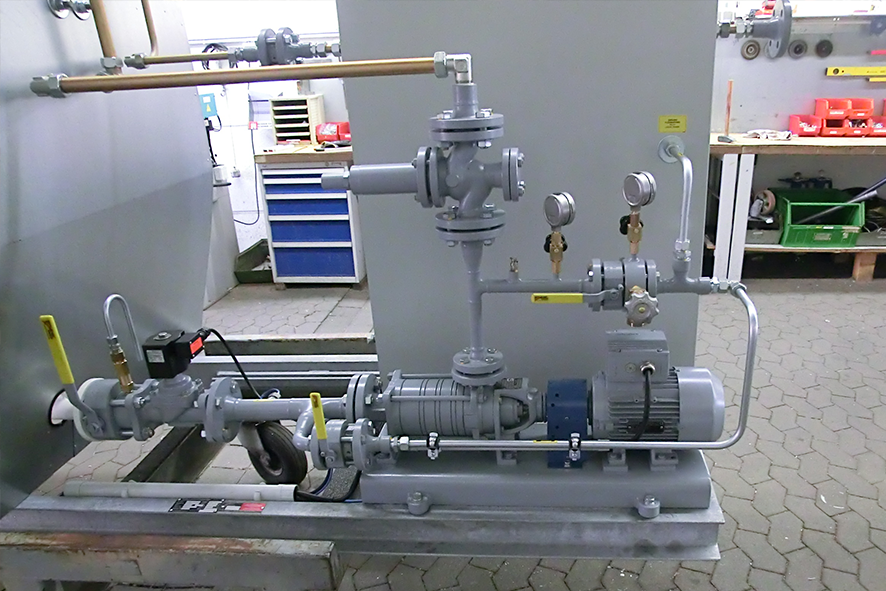

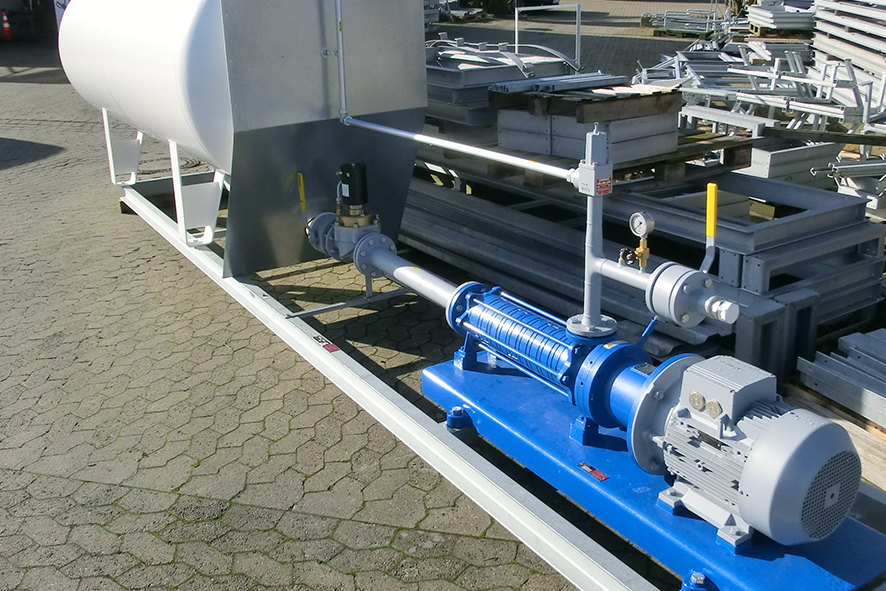

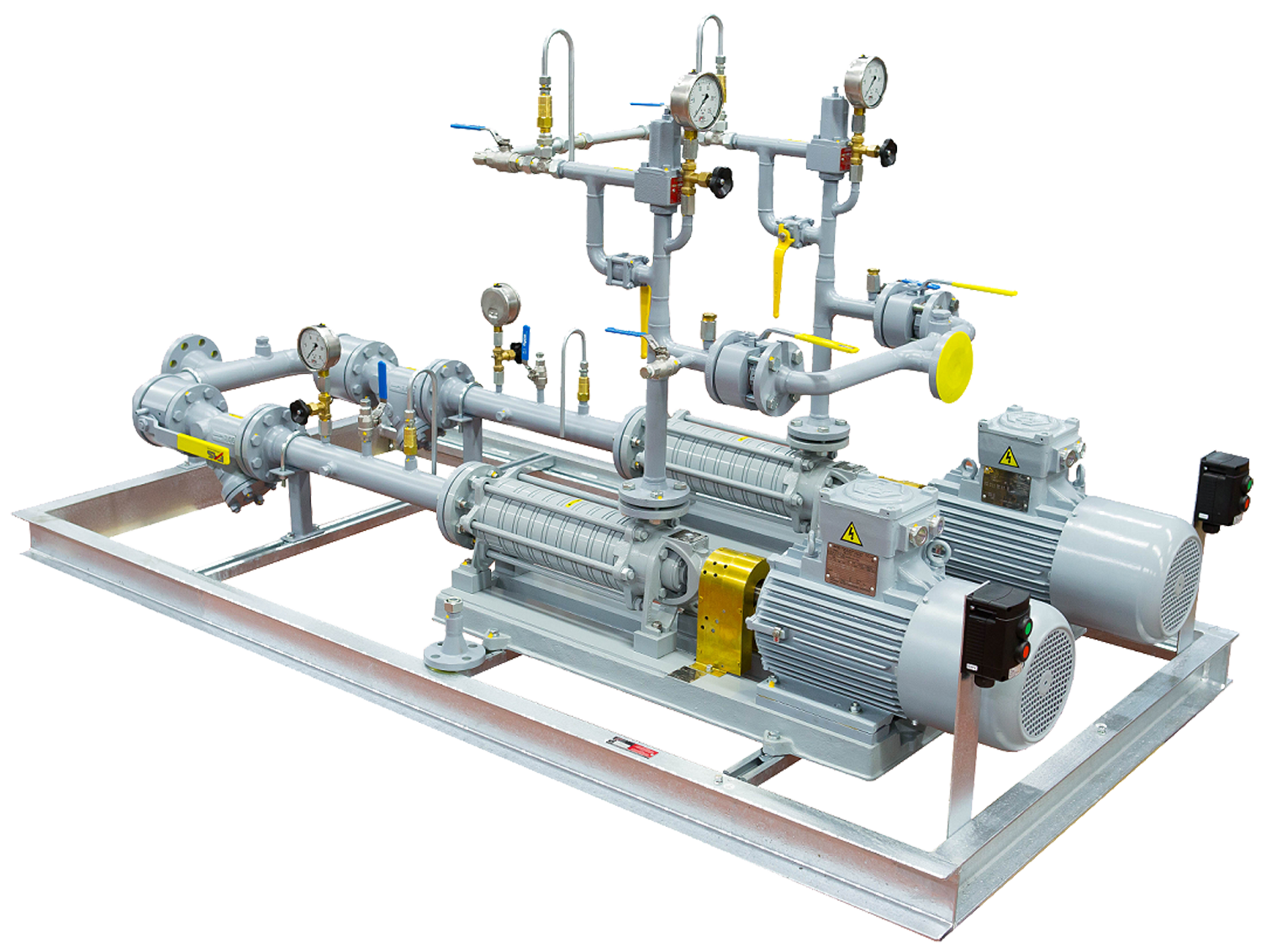

Les motopompes FAS pour le GPL sont installées dans les stations de remplissage AUTOGAS, dans la station de remplissage de gaz combustible, les terminaux et dans les camions-citernes afin de transférer le GPL d’un réservoir de stockage dans un autre réservoir par pompage, comme dans Autogas respectivement les réservoirs de gaz combustible, le réservoir de carburant camions, etc. Selon le type de pompe, les capacités varient entre 10 et 4500 litres par heure avec une pression différentielle de max. 14 bar.

Nos pompes d’aspiration et unités d’aspiration FAS sont disponibles dans les versions suivantes :

Configurations possibles:

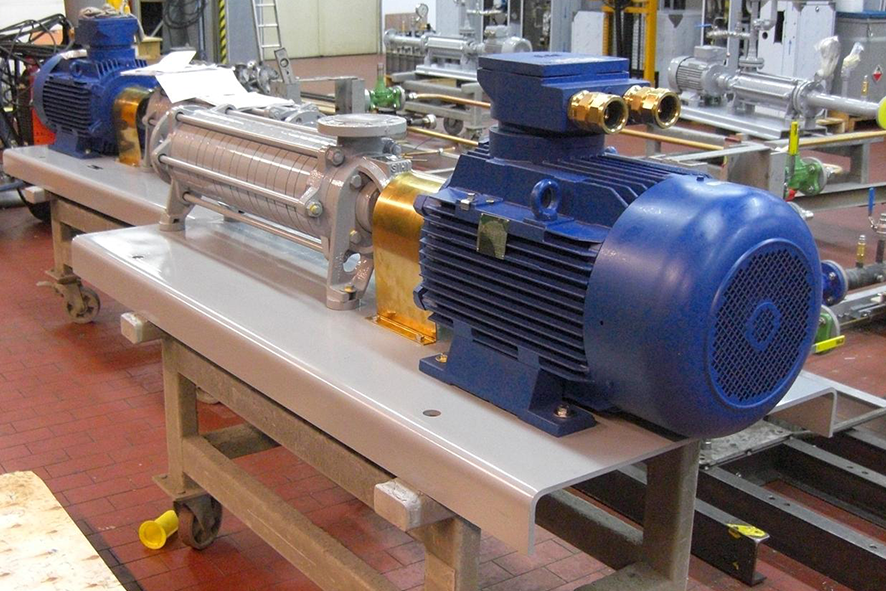

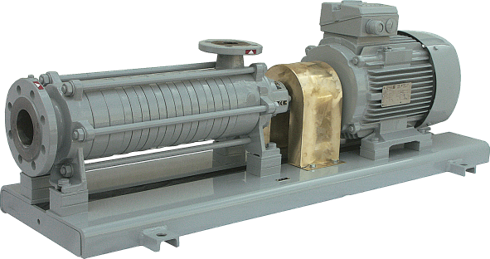

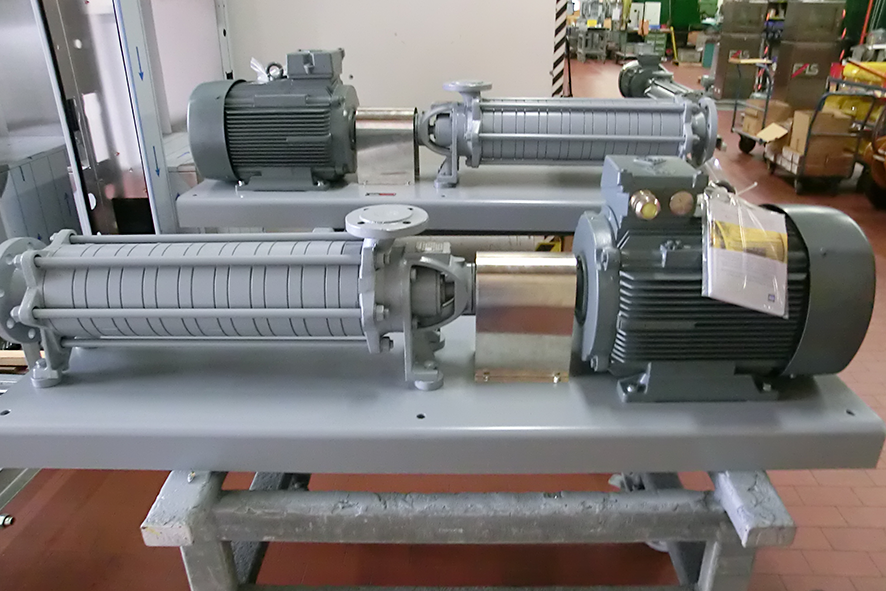

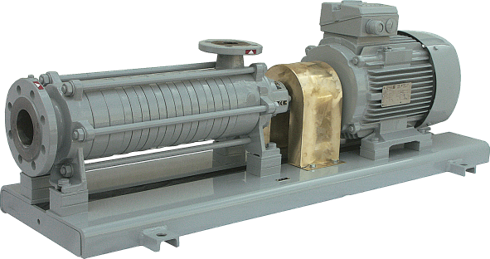

- Pompes à canal latéral GPL, Groupe moto-pompe à canal latéral GPL

- Pompes à turbine GPL, Groupe moto-pompe à turbine GPL

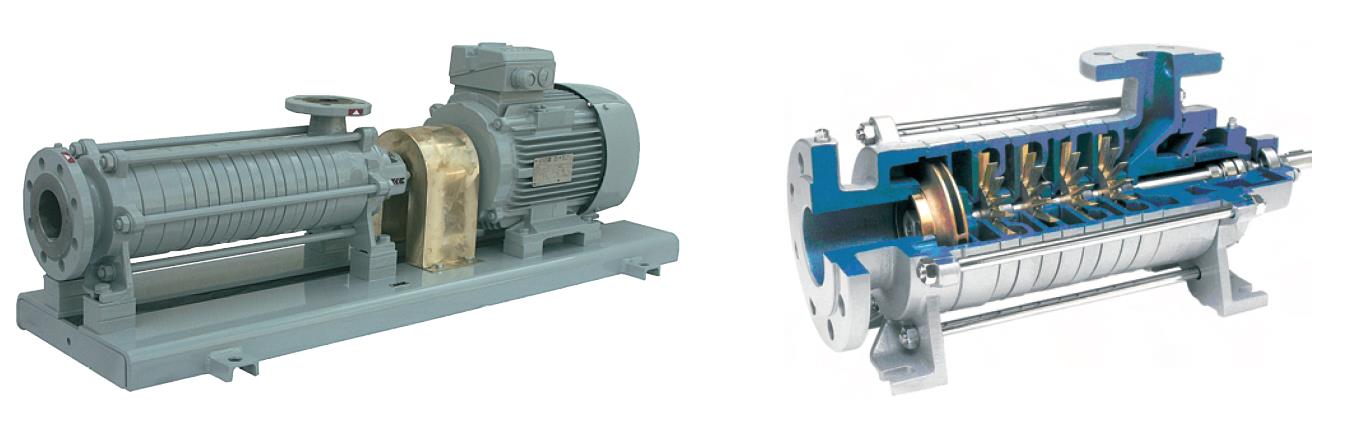

- Pompes centrifuges auto amorcante multicellulaires pour carburant et GPL, Groupe moto-pompe centrifuges GPL.

-

غاز مضخة مضخات تعبئة الغاز السائل

Petite sélection de types de pompes possibles :

- Corken FD-150 / FF-150

- Corken FD-150, Z-2000, Z-3200, Z-3500, Z-4200, Z-4500 / Z2000, Z3200, Z3500, Z4200, Z4500,

- Ebsra RC20,RC25

- SIHI SC2003, SC2004, CEH 1202, CEHB CEH 4102, CEH 6108, 5103. 5102. 5101. 5108. 5107. 5106. 5105. 5104. 5103, 3106. 3105. 3104. 3103. 3102. 3101, 3106/5 – 6108/5, 6107/5, 6106/5 ; 4108/5 ; 4106/5 ; 3108/5 ; 3106/5

- Viking GG-4195, HJ-4195, HL-4195

- Blackmer LGB1, LGL2 « , LGL 3 », LGL 4 «

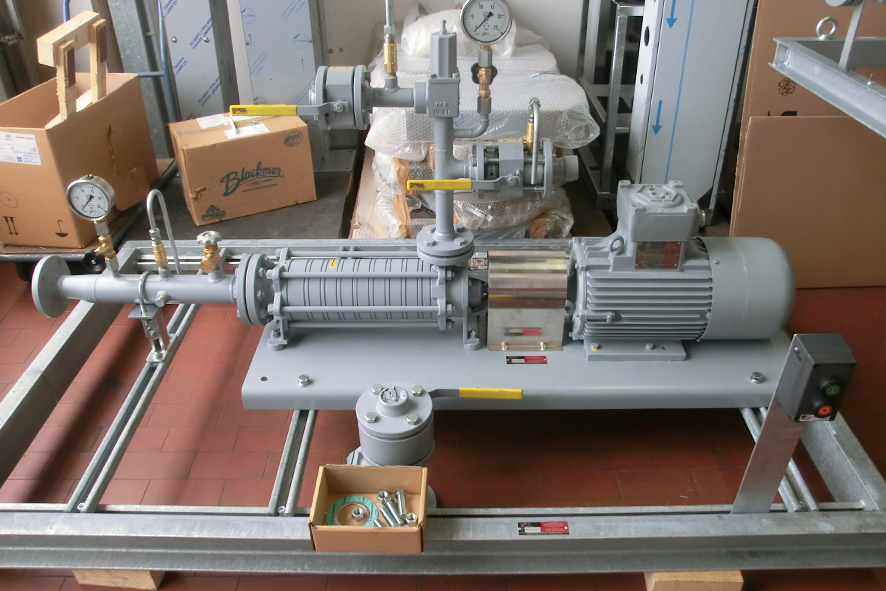

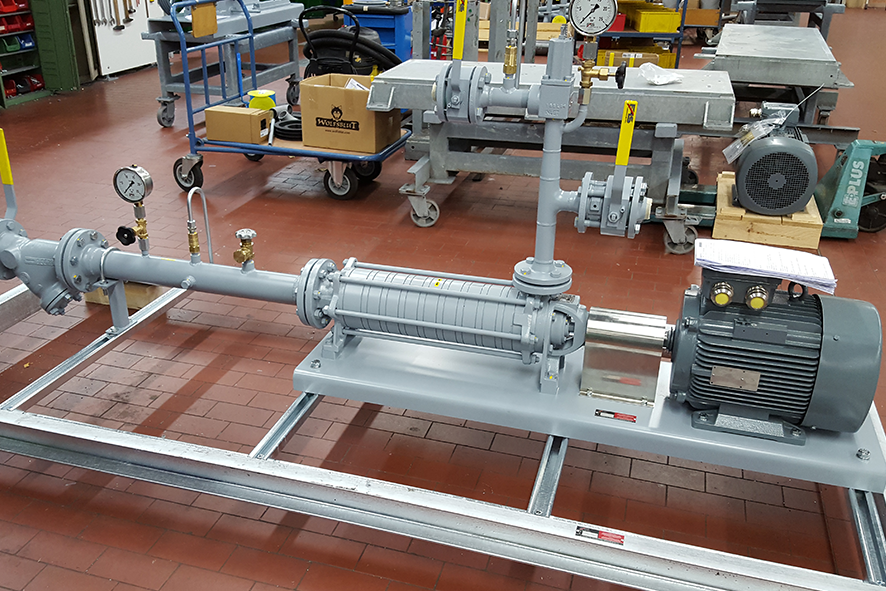

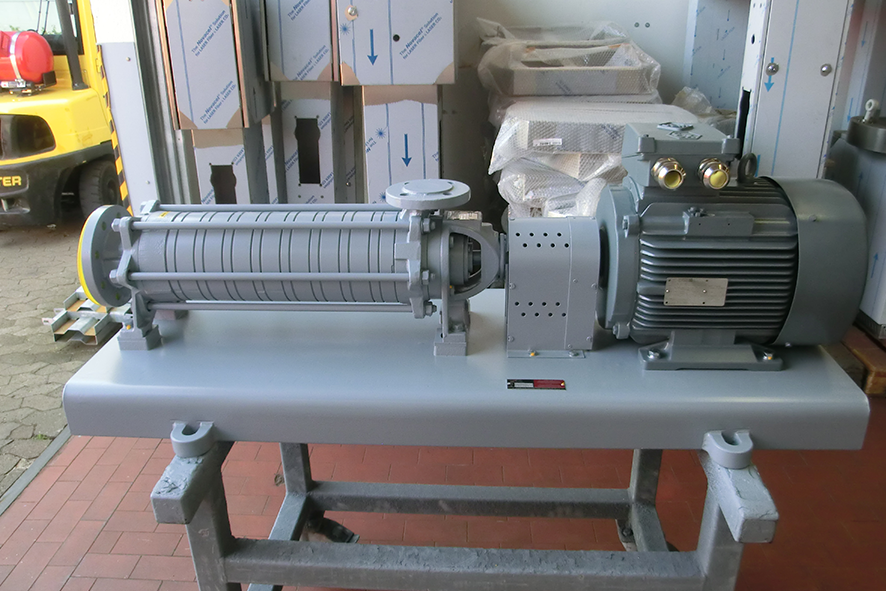

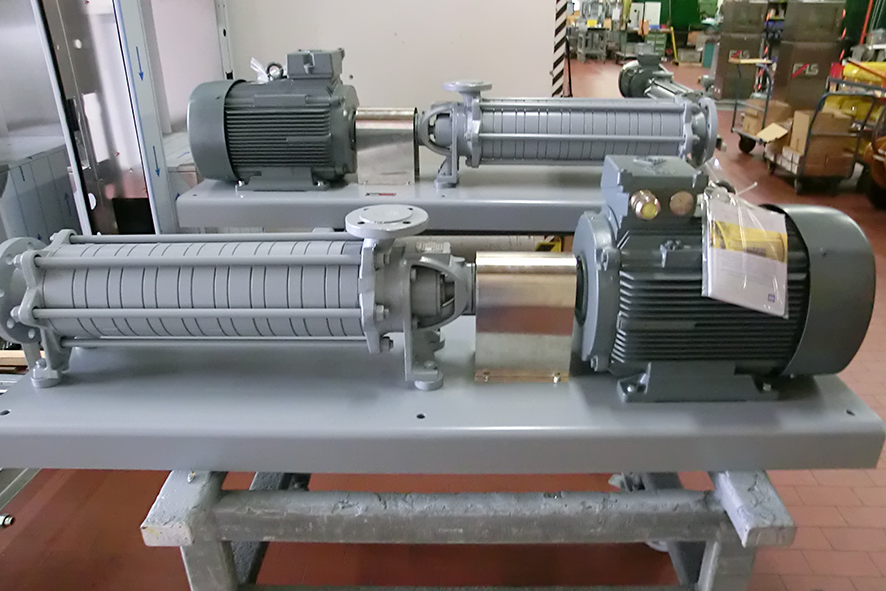

- Motopompe GPL Série FAS-NZ

- SIHI CEHA 3106/7, CEHA 3607/7, CEHA 3108/7,

- SIHI AEH 3506, AEH 3606, AEH 3607, AEH 3608,

- SIHI CEH 4106, 4106NL ,CEH 4107, CEH 4108, 4108/5, 4108NL

- SIHI CEHA 5106, CEHA 5107, CEHA 5108,

- SIHI CEHA 6106, CEHA 6107, CEHA 6108, 6108/5, 6108NL

- SIHI TLH / TKH 15102; 15003; TKHC 15004 ,15005, 15006, 10001, 10002,10003 ,10004, 10005, 10006, 10007, 10008, 15501,15502, 15503, 15504, 15505, 15506, 15507

- De nombreux autres modèles de pompes sur demande

- Entraînement électrique ou hydraulique

- Type de pompe avec option avec accouplement magnétique, double garniture mécanique, etc…

Nos motopompes submersibles FAS et motopompes submersibles FAS sont disponibles dans les versions suivantes:

- Ebsray RC25 RV40

- SIHI UEAB

- De nombreux autres modèles de pompes sur demande.

- Piéces de rechange et garniture mécanique disponible en stock.

Notre Offre inlcue la fourniture d’autres types de pompes:

- Pompe de régulation hydraulique

- Pompe à engrenage interne

- Pompe à lobes

- Pompe à vis

- Pompe centrifuge de process

- Pompe centrifuge horizontale

- Pompe centrifuge multicellulaire

- Pompe centrifuge verticale

- Pompe de forage

- Pompe doseuse à piston

- Pompe hélice coudée

- Pompe submersible

- Pompe volumétrique

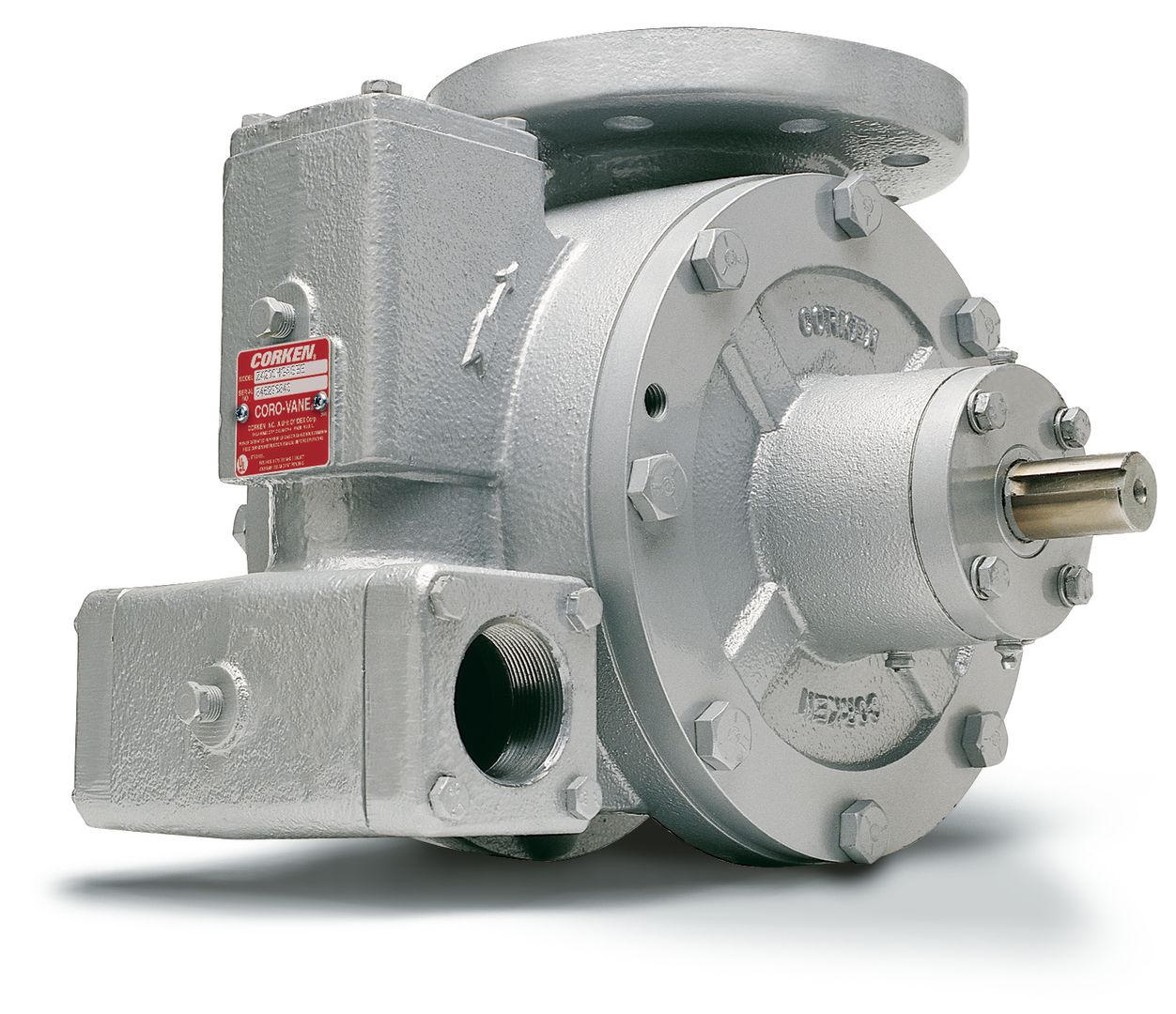

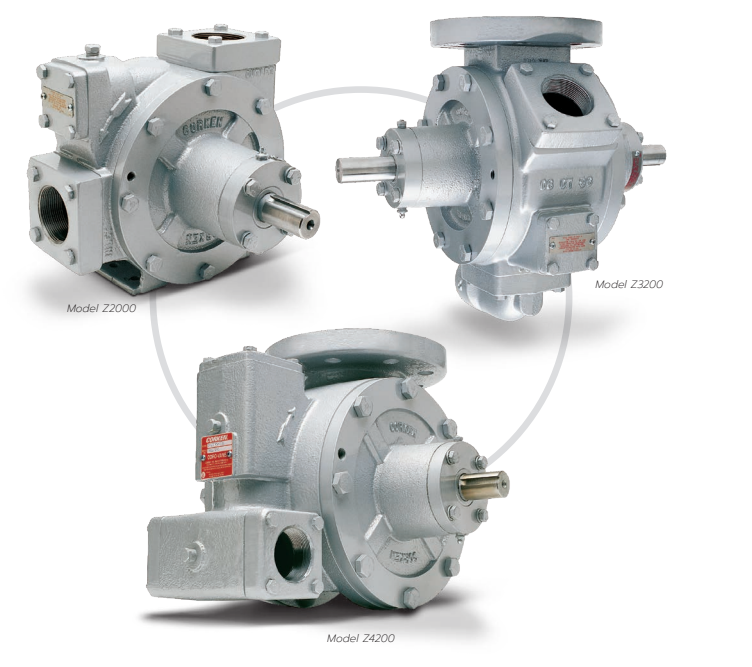

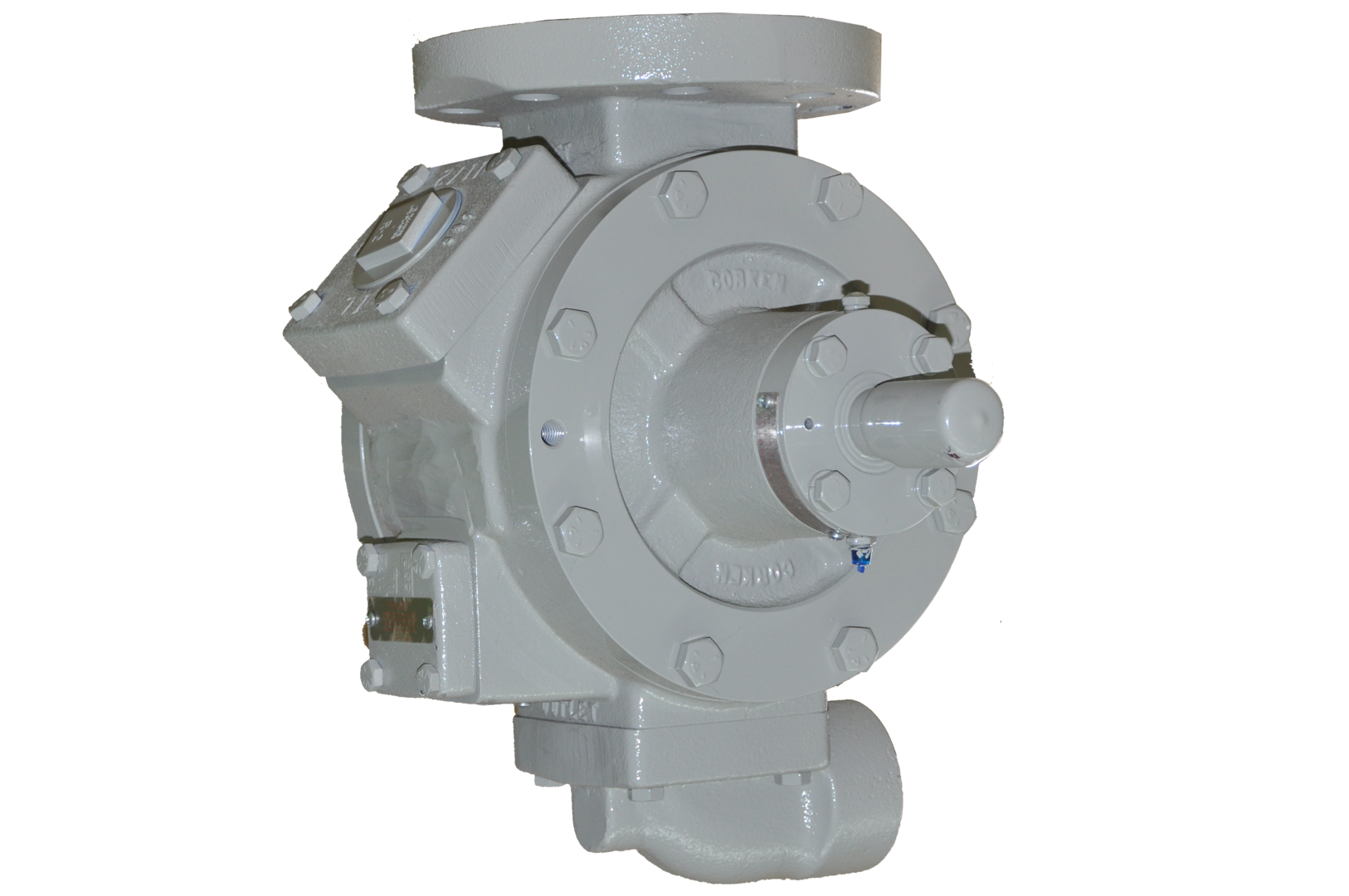

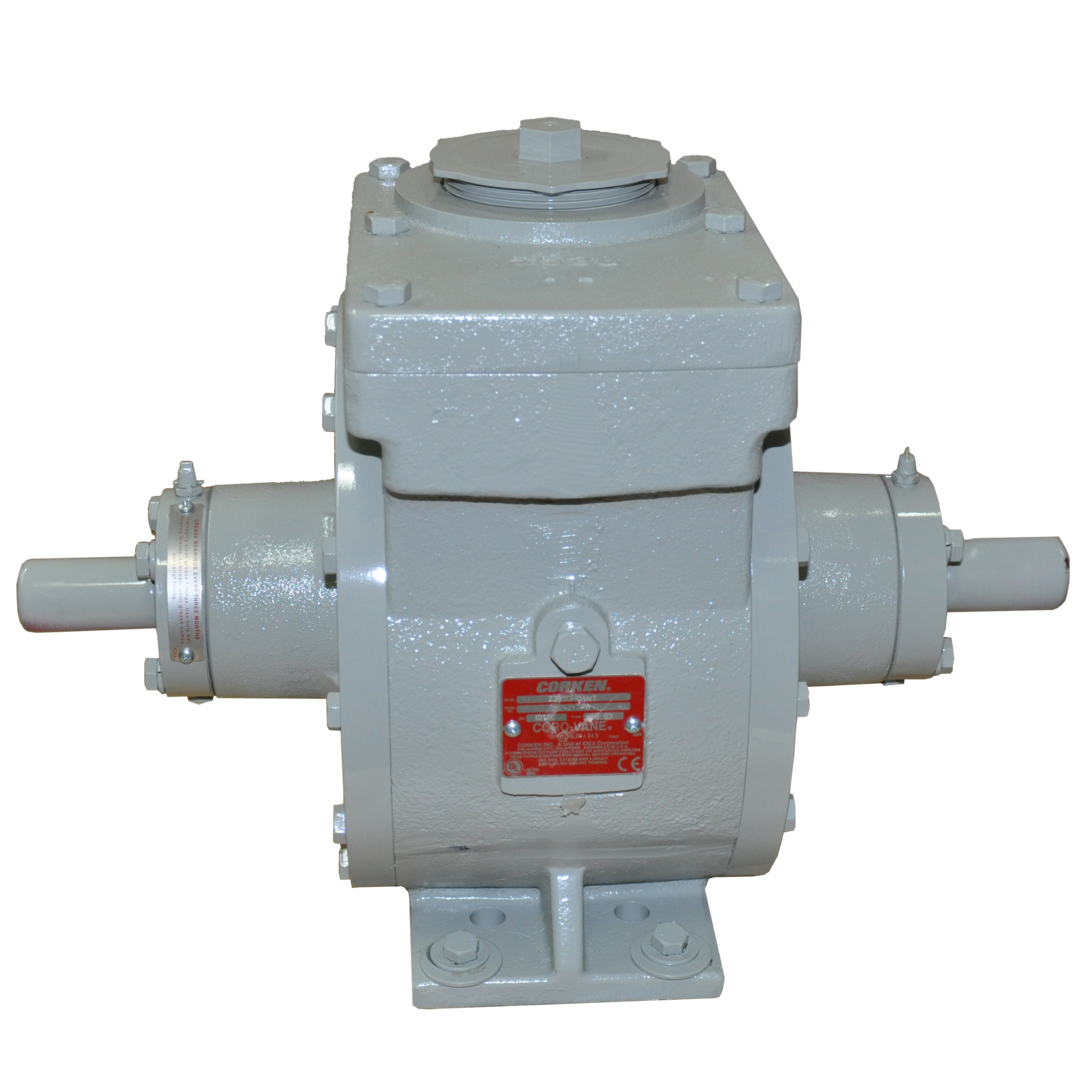

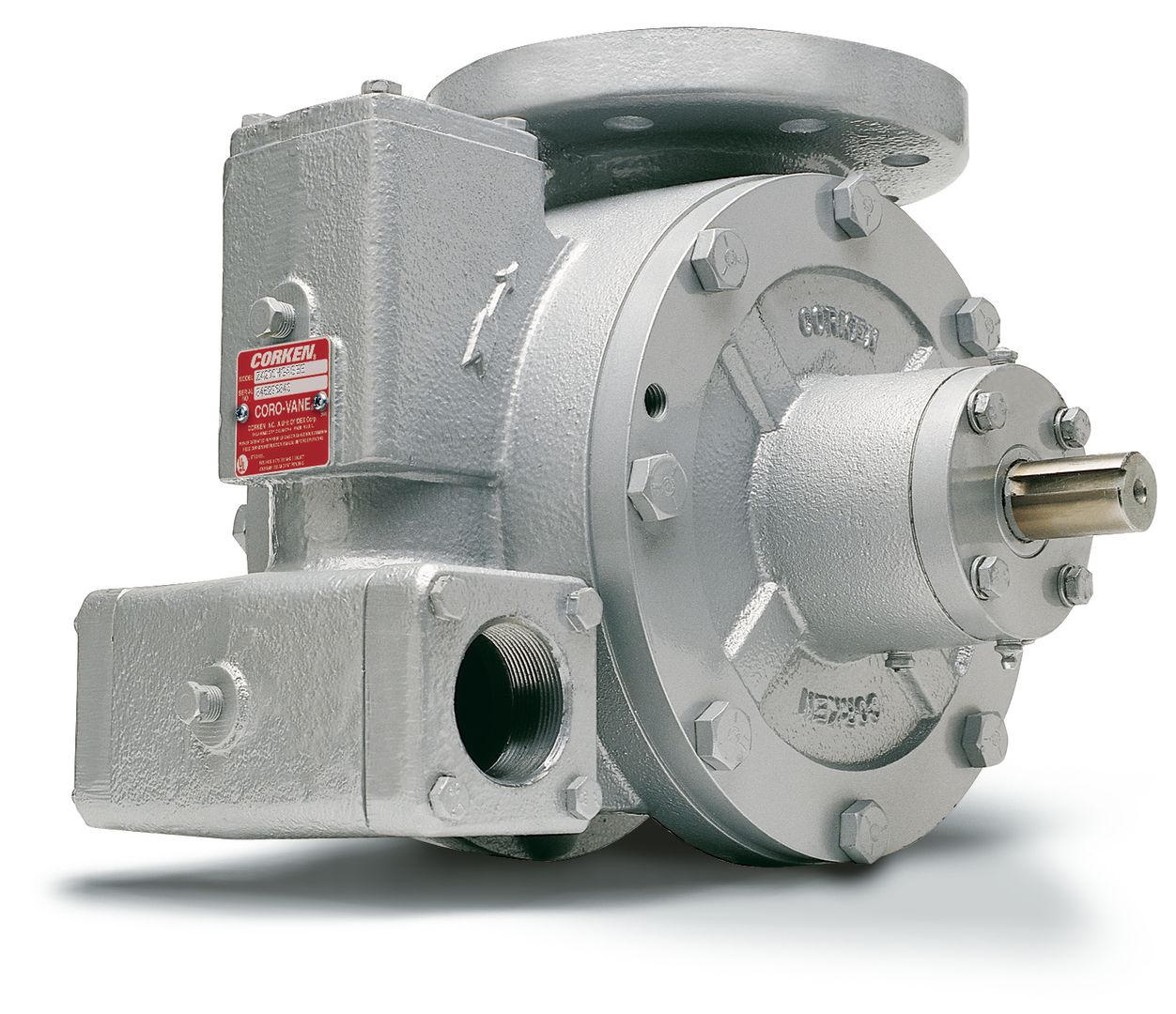

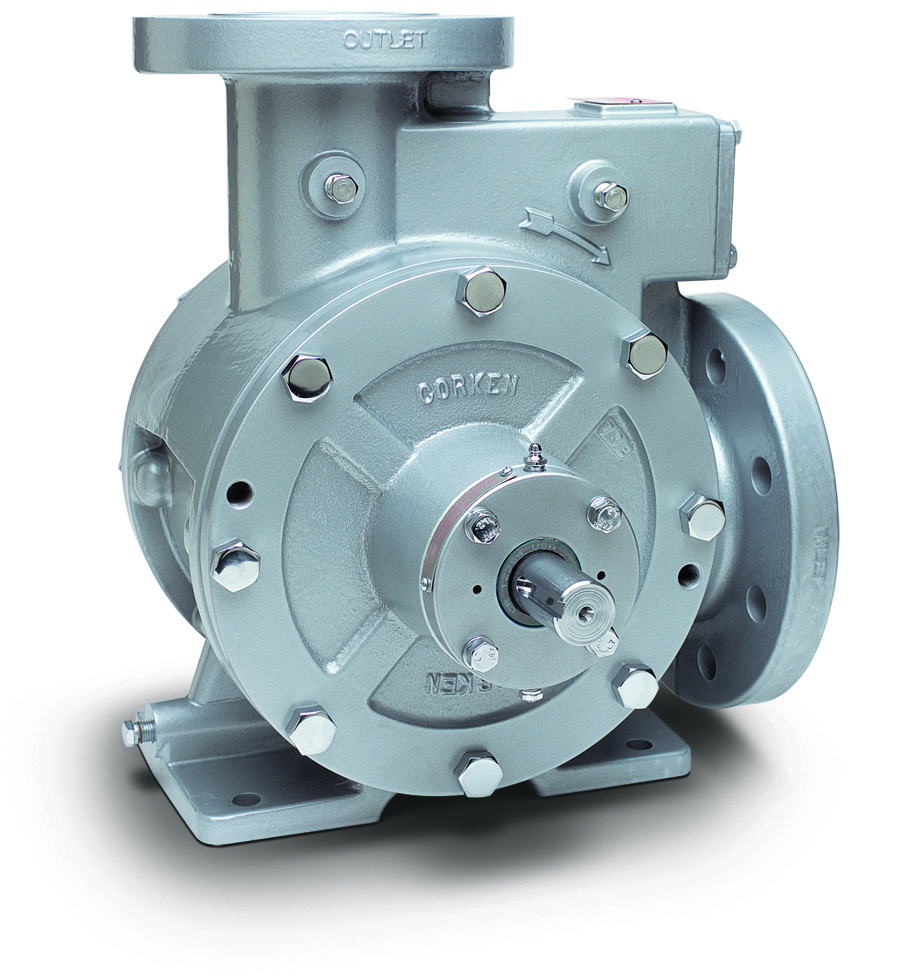

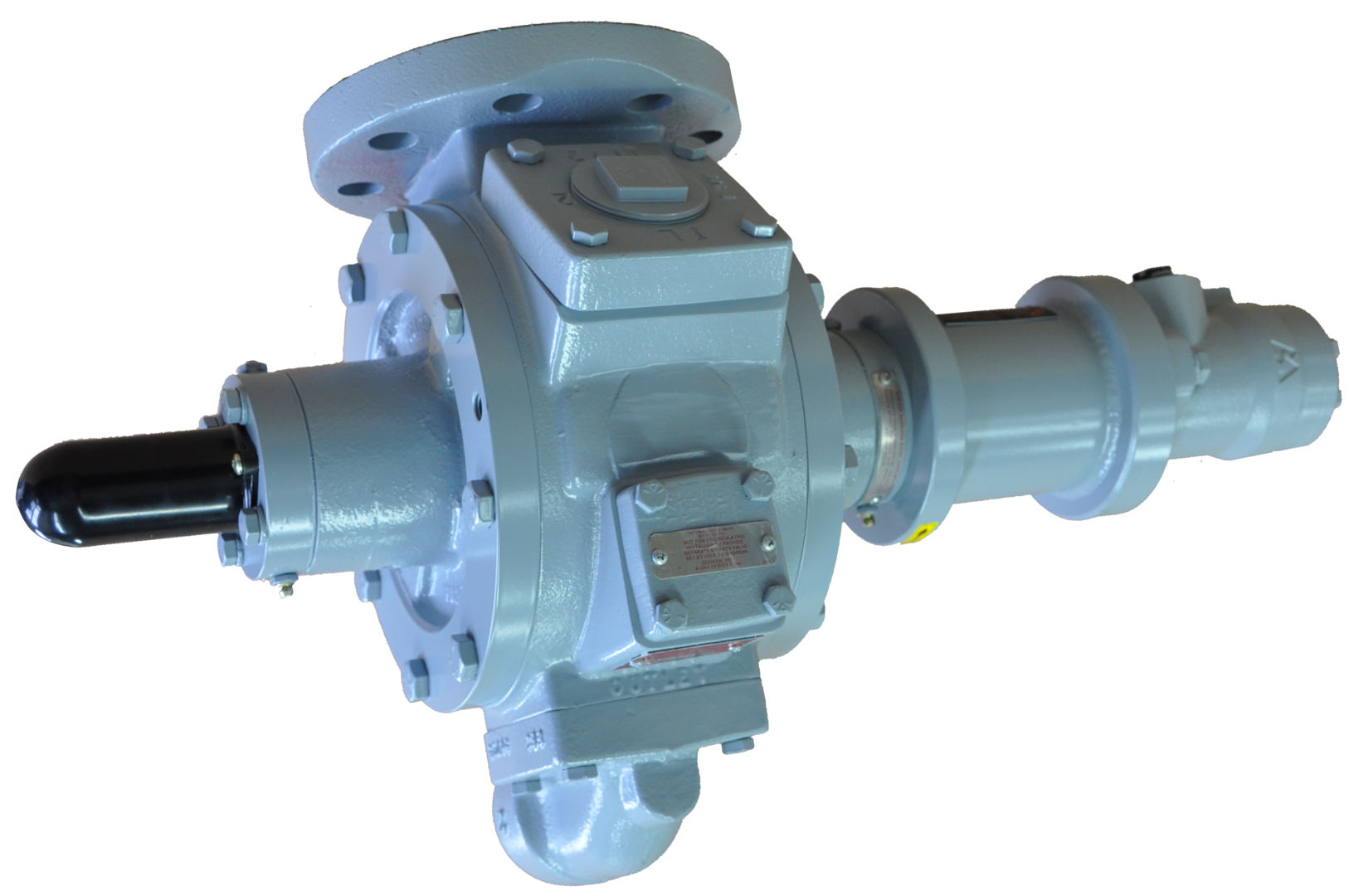

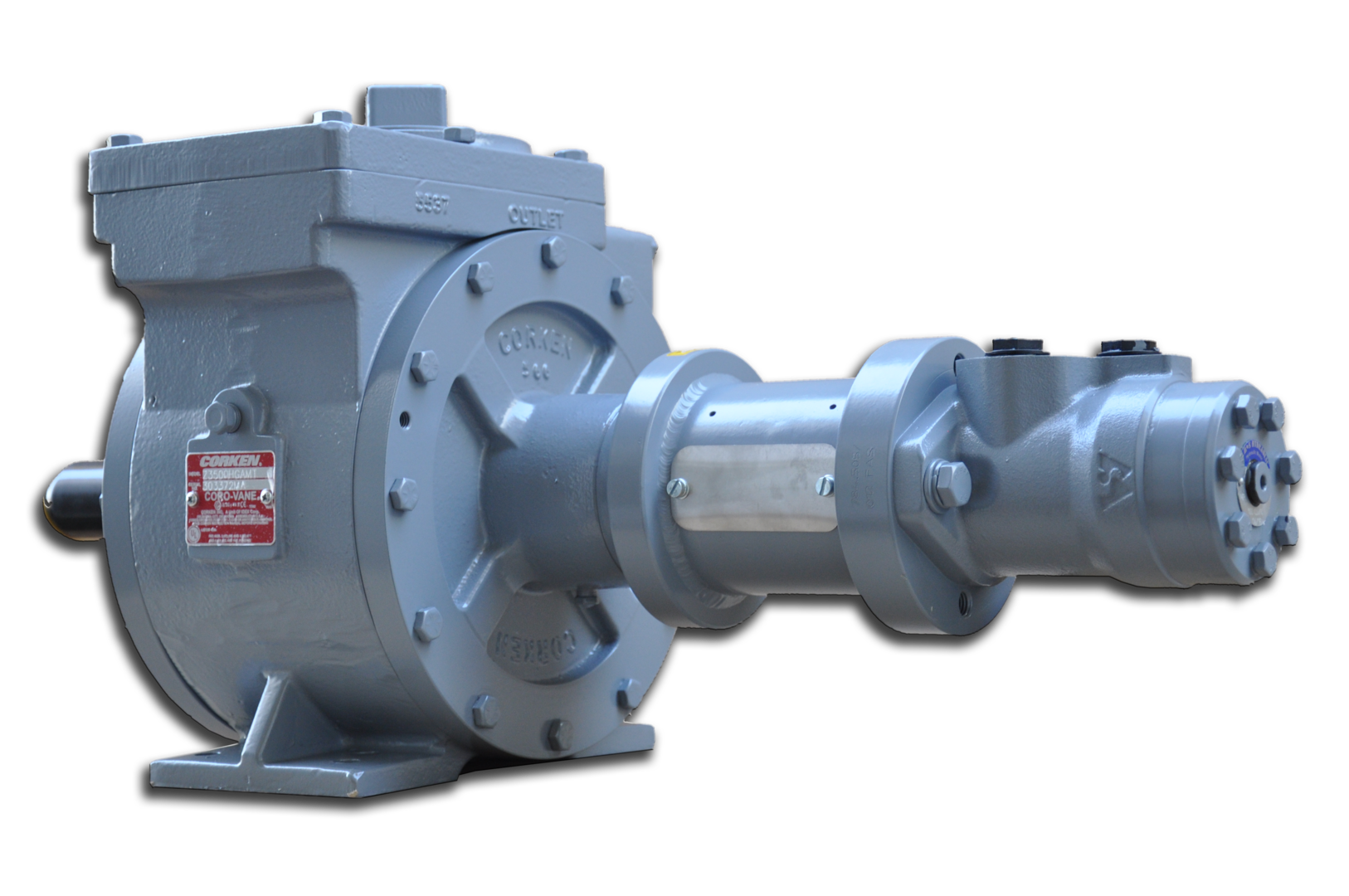

SLIDING VANE PUMPS Z2000; Z3200; Z3500; Z4200; Z4500

Application: LPG Road Tanker – LPG Terminals

CORKEN PUMPS Z MODEL SLIDING VANE VERSION: Z2000; Z3200; Z3500; Z4200; Z4500

A new generation of Corken pumps

The CORKEN pumps Z-Series are a new generation of truck pumps specifically designed to comply with the pumping requirements demanded by the LPG industry. Bulk delivery of LPG requires the use of heavy duty, reliable equipment and is an important part of every LPG marketer. The equipment used in modern bulk trucks must be designed and constructed to perform in a broad spectrum of operating conditions.

Meeting the Demands of Today’s Pumping Conditions

The operating conditions of a truck pump are very demanding, and only a pump designed to perform under these extreme conditions can successfully do the job day in and day out. The Corken pumps Z-Series are specifically designed to perform in such severe operating conditions as high differential pressure, pump overspeeding, poor suction conditions and heavy thrust loads associated with a power take-off (PTO) drive system.

- Controlling thrust loads and cavitation are critical for extended pump life.

- Large diameter non-metallic pins are not speed sensitive so you can operate the pump at a higher RPM and not damage the pump.

- High tech materials used on cam and blades extend the life of the pump.

- Up to 7% or more capacity at 640 RPM.

- Unlike other three-inch stationary pumps rated at 640 RPM, the Z3500 is rated up to 800 RPM providing higher capacity without damage.

- Maintenance is made simple. When it becomes necessary to service the pump, all you need to do is remove twelve head bolts to inspect the bearings, seals, sideplates, rotor, vanes and vane drivers.

- Retrofits the Corken model 1021 pump and other three-inch competitive pumps with little or no change in piping.

Corken pumps Z-Series available in 2”, 3” and 4” sizes known as Z2000; Z3200; Z3500; Z4200; Z4500 pumps

CONSTRUCTION:

- Designed for high pressure applications with a maximum working pressure of 27.6 bar

- Available in foot and truck mounted designs

- O-ring construction

- Six vanes/blades design with vane drivers

- Mechanically seal design with silicon carbide seal seat

- Depending on the model, available with NPT or Class 300 RF flanges

- Hydraulic drive option available

MATERIALS:

- Pump casing and heads: Ductile iron

- Cam and sideplates: Gray iron

- Rotor and flanges: Ductile iron

- Seal seat: Silicon carbide

- O-rings: Buna-N, PTFE, Viton®, Neoprene®. (Registered trademark of DuPont)

- Blades: Advanced polymers

FEATURES:

- Self-adjusting sliding blades and blade drivers maximizes performance

- Replaceable cam and sideplates and sideplates are reversible for twice the life

- Removing the pump head gives full access to the internals without disturbing the piping

- Can handle small amounts of vapor

- The excellent suction lift is great for clearing suction and discharge lines

- Internal relief valve is pre-set at the factory and is not adjustable

CORKEN PUMPS Z2000; Z3200; Z3500; Z4200; Z4500, bare

| type | FAS-Nr | capacity; l/min | dif. pressure, bar | flanges | weight, kg |

| Z2000 | 21296 | 220 | 10,5 | 2″NPT | 41,2 |

| Z3200 | 21297 | 450 | 8,6 | 3″ASME F/300-2″NPT | 55,6 |

| Z3500 | 21297 | 450 | 8,6 | 3″NPT | 55,6 |

| Z4200 | 21788 | 950 | 8,6 | 4″ASME/300-2″NPT | 113,2 |

| Z4500 | 21718 | 950 | 8,6 | 4″ASME/300-3″ASME/300 | 119,5 |

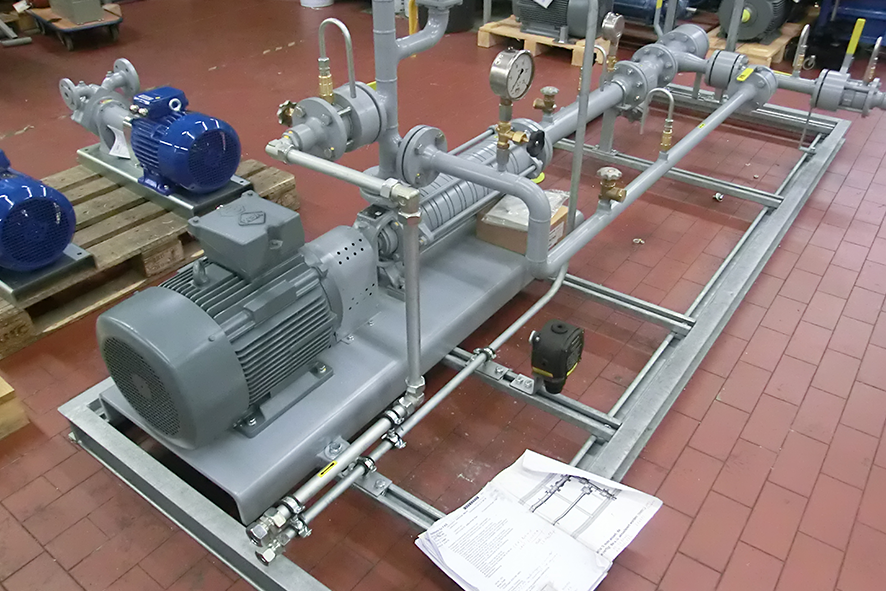

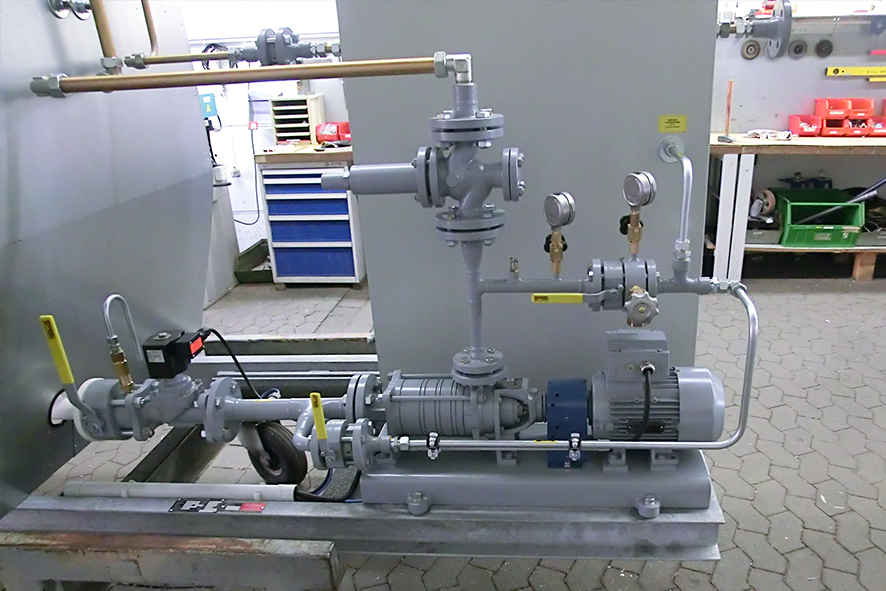

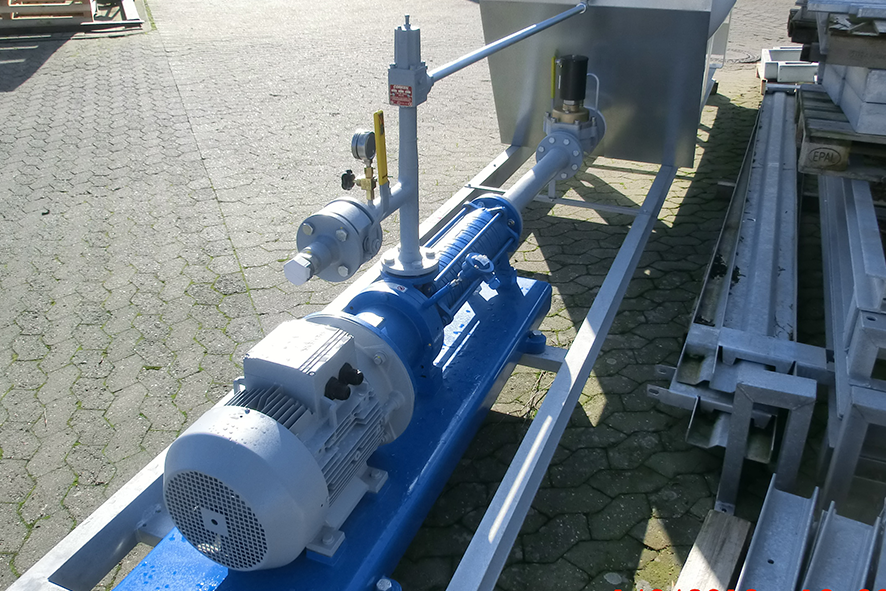

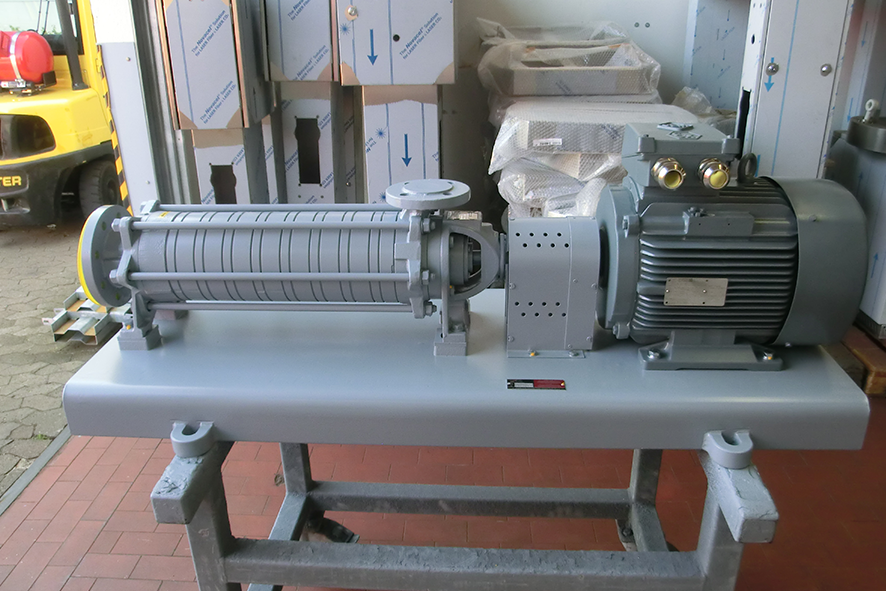

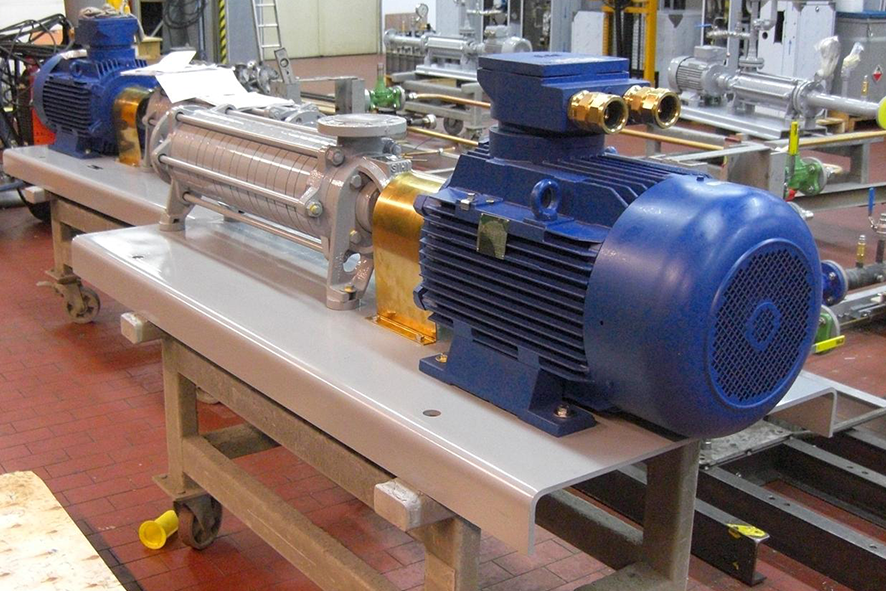

complete CORKEN pump units Z2000; Z3500; Z4500. Designed with E-Motor for stationery application. Designed and manufactured by FAS Germany

consist of: pump+motor +coupling+coupling protection+frame

| type | FAS-nr | capacity, l/min | design | motor, kW | weight, kg |

| Z2000 | 212251 | 220 | v-belt drived | 5 | 140 |

| Z2000 | 21225 | 220 | gear | 5 | 130 |

| Z3500 | 218089 | 490 | V-belt drived | 11 | 266 |

| Z3500 | 213160 | 490 | gear | 11 | 243 |

| Z4500 | 218088 | 950 | V-belt drived | 15 | 332 |

| Z4500 | 21808 | 950 | gear | 15 | 413 |

complete CORKEN pump units Z2000; Z3200; Z4200. designed for road tanker. Designed and manufactured by FAS Germany

consist of: pump+hydraulik engine+coupling+coupling protection

| type | FAS-nr | capacity, l/min | oil quantity, l/min | oil pressure, bar | weight, kg |

| Z2000 -OM80, 5,5 kW | 215720 | 220 | 58 | 100 | 52 |

| Z3200-OM100, 10kW | 21299 | 450 | 29 | 232 | 57 |

| Z3200-OM80, 8kW | 212993 | 400 | 52 | 110 | 57 |

| Z3500-OM100, 10kW | 21299 | 450 | 60 | 140 | 57 |

| CORKEN Z2000 | CORKEN Z32000 | CORKEN Z3500 | CORKEN Z4200 | CORKEN Z4500 | FAS-CORKEN Z3200 road tanker design | FAS-CORKEN Z3500 road tanker design |

|

|

|

|

|

|

|

Pompe blackmer LGLD 2″ – 4″

Application: LPG (liquefied petroleum gas)

As part of the Cavitation Line of sliding vane pumps, these LGLD propane pumps are ideal for propane, LPG, butane and anhydrous ammonia applications including bulk plant service, multiple cylinder filling applications, vaporizers, bobtails and transports. All LGLD propane pump models have an internal relief valve, and a replaceable casing liner and end discs for easy rebuilding of the pumping chamber if ever necessary. In addition, these pumps feature cavitation suppression liners to reduce noise, vibration and wear.

Blackmer® LGLD2 propane pumps are often mounted to the chassis of a bobtail, or to a steel pad that is welded to the tank. The 3- and 4-in rotary vane pump models can be mounted to a transport in a number of different ways, generally near or between the tank landing gear brackets.

BLACKMER LPG-PUMP, bare

for positove suction head, with mechanical seal, pump case material ductile iron ASTM A 536

| Type | FAS Nr | capacity, l/min | max diffrential pressure, bar | connections | weight, kg |

| LGLD 2 | 21305 | 220 | 10,5 | 2″NPT | 40 |

| LGLD 3 | 21306 | 490 | 10,5 | 3″NPT | 74 |

| LGLD 4 | 21337 | 950 | 10,5 | 4″ NPT | 99 |

FAS-BLACKMER PUMP UNITS

| TYPE | FAS-Nr | motor, kW | gear type | wight, kg |

| FAS-LGL2 | 21315 | 5 | gear motor* | 130 |

| FAS-LGL3 | 21316 | 10 | gear motor* | 230 |

| FAS-LGL4 | 21317 | 15 | gear motor* | 420 |

* Economy-design with V-belt pulley available.

BLACKMER FAS-PUMP UNIT in ROAD TANKER DESIGN

| TYPE | FAS-NR | MOTOR, HYDRAULIC | CONNECTIONS | Ol quantity, l/min | Ölpressure, bar |

| FAS-LGL2E /OM80 | 21572 | OM80, 5 kW | 2″NPT | 58 | 100 |

| FAS-LGL3F/OM100 | 21574 | OM100, 10kW | 3″NPT | 60 | 140 |

| FAS-LGL3F/OM 100 | 21578 | OM100, 10 kW | Schweissanschlüss 3″ | 60 | 140 |

Demande de devis: sales@fas-northafrica.com

Pour plus de renseignements, au Cameroun, cote d’ivoire, Tunisie, Algérie, Maroc, Burkina, mali, Niger, Senegal, Congo, Guinée, concernant nos POMPES GPL n’hésitez pas à nous contacter