OUR PRODUCTS  CYLINDER FILLING PLANT

CYLINDER FILLING PLANT

Cylinder Filling Plant

|

|

|

|

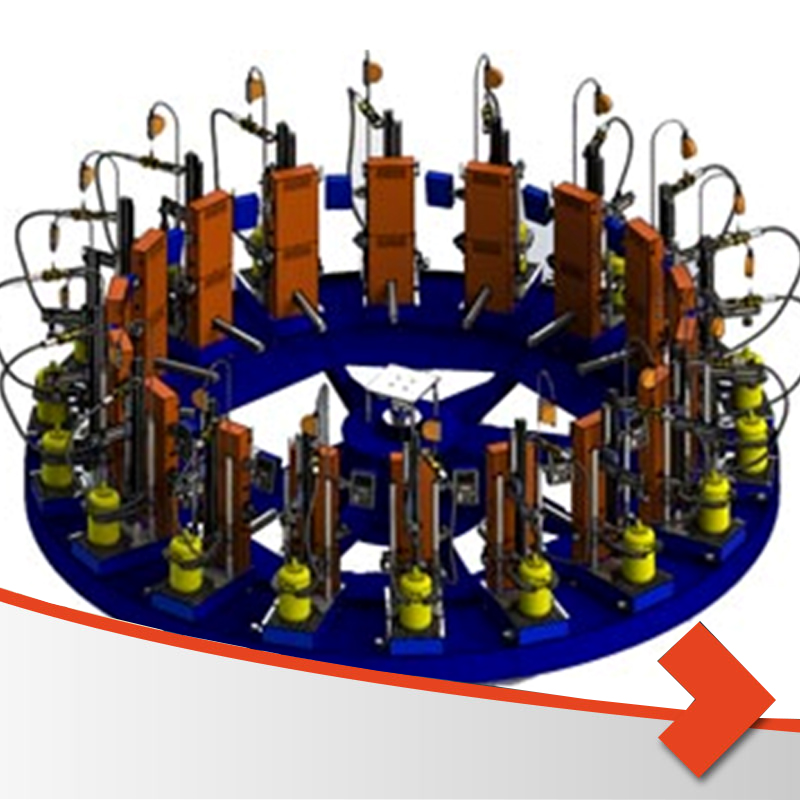

Carousel Filling Plant K18E with Filling Scale Type WAER |

Carousel Filling Plant K18E with Filling Scale Type WAER100 ex/e |

Carousel Filling Plant K18E with Filling Scale Type WAES |

|---|

These LPG carousel filling (Bottling) plants are particularly used for filling systems with a higher filling capacity. The cylinder conveyance to one of the max. 24 filling scales on a closed circular platform as well as the transport to the testing and control systems is carried out automatically by means of a chain conveyor with pneumatic auxiliary equipment. The continuous adjustment of the rotational speed of the platform allows the adaptation to the size of cylinders to be filled. The type of construction allows a maximal filling capacity with a minimal employment of staff.

The cylinder filling carousel plants are available in following executions:

- Electronic filling carousel K5E with 5 filling scales, capacity max. 250 cylinders per hour with 11 kg-cylinders respectively 180 cylinders per hour with 21 kg-cylinders

- Electronic filling carousel K7E with 7 filling scales, capacity max. 320 cylinders per hour with 11 kg-cylinders respectively 240 cylinders per hour with 21 kg-cylinders

- Electronic filling carousel K12E with 12 filling scales, capacity max. 600 cylinders per hour with 11 kg-cylinders respectively 410 cylinders per hour with 21 kg-cylinders

- Electronic filling carousel K18E with 18 filling scales, capacity max. 900 cylinders per hour with 11 kg-cylinders respectively 660 cylinders per hour with 21 kg-cylinders

- Electronic filling carousel K24E with 24 filling scales, capacity max. 1200 cylinders per hour with 11 kg-cylinders respectively 890 cylinders per hour with 21 kg-cylinders

Possible options and configurations:

- Following LPG filling scales are available:

-LPG filling scales not suitable for calibration:WAB 90 p

-LPG filling scales suitable for calibration: WAER, WAER 50ex/e-i, WAER 100 ex/e - Check scale WER 100 ex

- Tightness testing units MED, AED and AED2

- Shrinking machines MS and AS

- Evacuation units E1Ka, E2Ka, E3Ka, E4Ka, E5Ka

- Cylinder washing system WS

- Wireless data transfer from filling scale to PC for further handling and evaluation with optionally available software NLT

- Aboveground or underground storage tank system with corresponding pump

FAS Cylinder Filling Plant Technology for LPG – Inline Filling Systems with Roller Conveyor

|

|

|

Inline Filling Systems with Roller |

Inline Filling Systems with Roller |

|---|

Inline filling systems with powered roller conveyor can be equipped with max. 6 filling scales. The cylinders reach the filling station at irregular intervals. The transport of cylinders between filling scales, check scale, tightness testing unit and shrinking machine is facilitated for the operator by the use of roller conveyors. Due to the slight slope of the roller conveyor the transport of the gas cylinders takes place automatically.

Possible options and configurations for the cCylinder bottling plant :

- Following LPG filling scales are available:

-LPG filling scales not suitable for calibration:WAB 90 p

-LPG filling scales suitable for calibration: WAER, WAER 50ex/e-i, WAER 100 ex/e - Check scale WER 100 ex

- Tightness testing units MED, AED and AED2

- Shrinking machines MS and AS

- Evacuation units E1Ka, E2Ka, E3Ka, E4Ka, E5Ka

- Cylinder washing system WS

- Wireless data transfer from filling scale to PC for further handling and evaluation with optionally available software NLT

- Aboveground or underground storage tank system with corresponding pump

LPG Inline Cylinder Filling Systems are available in following executions:

- Manual inline cylinder filling plant with roller conveyor and 1 up to 6 filling scales, max. 20 – 180 cylinder per hour with 11 kg

Additionally we offer the following:

- Planning and turnkey project handling

- Supply of plug-in version

- Project-related system control

- Complete installation and commissioning

- Service and Maintenance